HVAC BRAZED JOINT LEAK TEST SYSTEM

January 4, 2017

Market Driver:

The manufacturer of HVAC systems needed a system to test brazed joints at final assembly for being leak tight. There are several joints of different sizes that must be tested for a rate of one 10th of an ounce of refrigerant Freon loss per year. Conventional ‘sniff-type’ leak testers did not provide the accuracy and repeatability they needed to meet quality standards. In the past leak test methods on similar products resulted in false leak failures slowing down production and adding cost to the product. The manufacturer of HVAC systems needed a system to test brazed joints at final assembly for being leak tight. There are several joints of different sizes that must be tested for a rate of one 10th of an ounce of refrigerant Freon loss per year. Conventional ‘sniff-type’ leak testers did not provide the accuracy and repeatability they needed to meet quality standards. In the past leak test methods on similar products resulted in false leak failures slowing down production and adding cost to the product.

CTS Test Solution

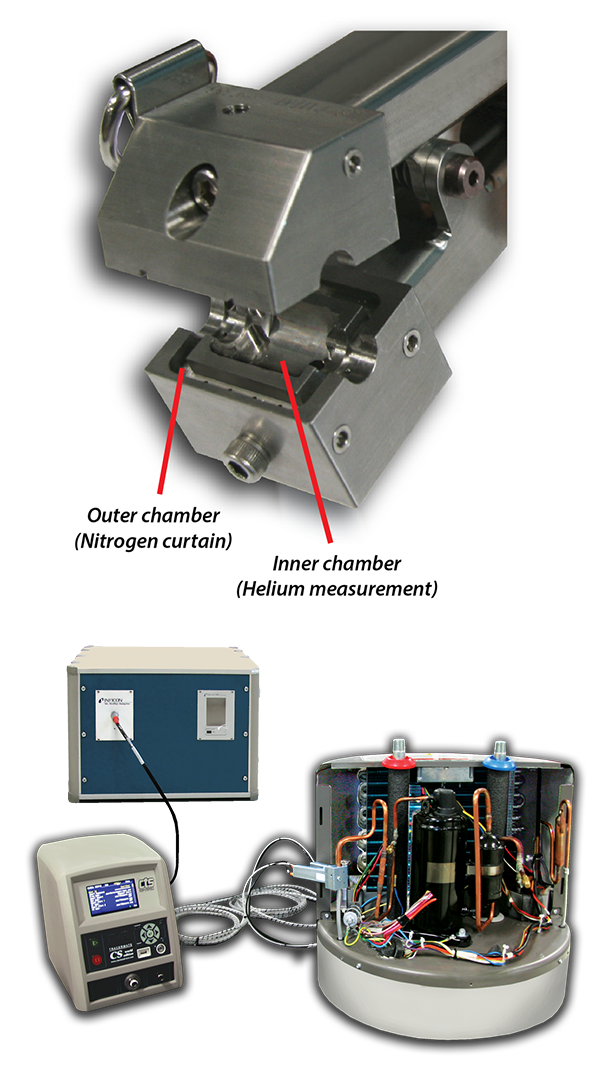

CTS designed a tracer gas test solution that utilizes our patented Nitrogen Purge clam shell design in a hand-held configuration. The hand-held purging clam shell is a small custom designed test fixture that can be easily maneuvered and clamped over the brazed joints. The purging clam shell design utilizes low pressure Nitrogen curtain to create a ‘Helium-free’ test environment for the Mass Spectrometer to sample and detect micro-leaks at the joint being tested.

The CTS clam shell device has inner and outer chambers that surround the part test area. The chambers have ports to allow low-pressure Nitrogen to enter the cavity and force out ambient atmosphere. During the leak test cycle, the inner chamber collects the tracer gas leaking from the part. The outer chamber provides a constant low positive pressure Nitrogen curtain to hold back and prevent ambient background from entering, effectively isolating the inner chamber. This isolation increases sensitivity to detect Helium, effectively eliminating false leak failures and improve leak test accuracy.

This tracer gas system utilizes the CTS TracerMate CS tracer gas management system that provides system evacuation, test pressure, gross leak test, tracer gas backfill, and system exhaust processes. The TracerMate CS is easy to integrate with the Mass Spectrometer helium detector to control operation and manage test results.

Project Summary

Nitrogen Purge provides superior background control and reduces the need for larger chamber hard vacuum test systems for many applications. This patented technology increases the sensitivity of ‘sniffer-type’ leak detectors to reduce background to 10-6 atm-cc/s range to detect micro-leaks with repeatable accuracy. The hand-held purging clam shell design is a small and customizable to fit a broad range of heating and cooling applications. The Nitrogen Purge clam shell fixture design is also available in a benchtop configuration.

Attachments:

|